Content of technology transfer items

1. According to the needs of users and the sites customers provide, we design reasonable production line. Besides, we transfer production formula and process, as well as train workers to produce qualified goods according to process requirements.

2. We provide list of equipment procurement, while we assist customers purchase equipment and instruments and we are also responsible for directing the installation and commissioning of equipment.

3. Then, we can help users design and direct the manufacture of laboratory, which is able to inspect raw materials and finished products.

Products in technology transfer items

It includes concrete admixtures powder or liquid mixing equipment, naphthalene-based superplasticizer of SNF, SFN and PNS type, polycarboxylate superplasticizer, amino sulfuric acid-based superplasticizer, aliphatic high-range superplasticizer, melamine superplasticizer and dry mortar.

Success cases

success cases include Saudi naphthalene superplasticizer project transfer, India naphthalene superplasticizer cooperation project, Vietnam melamine superplasticizer transfer project, Dubai admixture laboratory project, Wuhan dry-mixed mortar production line project and Hubei polycarboxylate superplasticizer project.

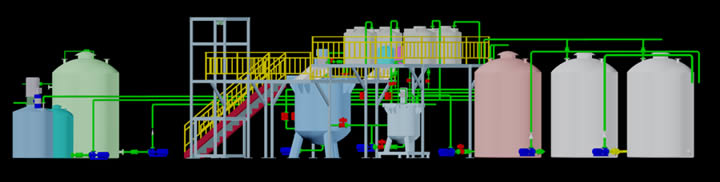

Featured Project - New Production System for Polycarboxylate Superplasticizer (MH-PCL-2A)

Energy saving Production: The production system is operated under normal water temperature. No heating source or cooling system is necessary in the production.

All-in-one Design: Chemical synthetic and physical blending process can be accomplished in the same machine. Concrete admixtures tailored for RMC can be produced directly from raw chemical materials by this one unit.

Customization: Product formula as well as the production line layout can be adapted to resources and limitations on site.

Easy operation: Automatic control not only guarantees stable product quality, but also saves labor hours and troubles.

High-tech Products: Product quality is comparable with worldly known enterprises such as BASF and SIKA. The EXW cost of finished product is around $0.4/Liter.

Low Investment: Total investment on equipment is around $50,000 to achieve daily production capacity of 50 tons.

Quick Delivery: Establishment of the production line can be finished in 30 days.